To: Northern Arizona Proposed Withdrawal Project

ATTN: Scott Florence

Bureau of Land Managment

From: Nancy Freeman

Groundwater Awareness League, Inc.

P. O. Box 934

Green Valley , AZ 85622

Date: May 4, 2011

To assist in viewing tables this report can be viewed on website link:

www.mining-law-reform.info/GrandCanyonII.htm

As I write these comments I have a sense of what the inspired people who created the Grand Canyon National Park would be thinking now if they knew that U.S. citizens have to protest the takeover of the region by uranium mining operations. They would be also stuck with awe at the devastation humans and their technology have inflicted on the planet. In the past 100 years, humans, particularly Americans, Canadians and British, have produced more pollution and more devastation to the environment than the previous thousands of years of mankind. The Native Americans inhabited the region for thousands of years and hardly left a trace, let's see how fast the “Europeans” can destroy it for profit.

The present rush to mine at the Grand Canyon is because the price of uranium is up. When 1,000 new mines start operating around the world, the price of uranium will go down. Unfortunately, the current market system has no planning to create a steady flow of each metal to meet demand, but operates with a boom and bust system, as everyone goes for mining when the price is high. At the bust, many small mining companies take bankruptcy and leave the mines unreclaimed.

Mining in Arizona is especially vulnerable. Here a mining company is not required to post actual money for reclaimation. If they have adequate credit at the time of the permitting, they are permitted. Of course, this would draw companies with questionable stability, which are created overnight to take advantage of the uranium price and cheap government land and free water. Even if the mining company reclaims the property, it can take many years. Freeport-McMoran just completed the reclamation of uranium-contaminated groundwater (due to cooper mining) at the Tohono O'odham site at North Komelik, formerly owned by Cyprus , 30 years after closure—at a cost of $49 million.

At the present time, the demand for uranium for nuclear power plants is an unknown. Even so, there are many mines already in operation that can produce adequate uranium, plus there are many others that are gearing up because of the current higher uranium price.

Therefore, there is no need to sacrifice the integrity of the habitat in special places and critical watersheds. Further, there is evidence that with current technology uranium waste can be recycled; enough for 200 years, so there is no need for uranium mining. Also, there is developing technology to take uranium from sea water, which will eliminate the need for uranium mining—within 20 years.

If we take a look at the region from the Google Earth perspective, we see that the region was protected because of the forest and vegetation that created habitat for wildlife and human recreation. The region around the Grand Canyon is an island of green in a sea of desolation.

http://maps.google.com/maps?hl=en&ie=UTF8&t=h&ll=36.175574,-112.077026&spn=1.081925,1.755066&z=9

There is data showing that the removal of trees in the rain forest causes less rain and produces drought conditions. At present, there is not enough data to ascertain how the elimation of a smaller number of trees will affect rainfall and the ecosystem. Experts have opined that the reason for the demise of Chaco Canyon culture was their cutting of the trees, which provided the ecosystem to bring in and sustain rain. We need our trees and vegetation to be kept in place. Arizona and the Southwest have miles of wastelands—why create another one? Even though it is supposed that the number mines will be a relatively small, but multiplied by an unknown number of mine, no one knows. The recent surge in mining claims shows what could happen if permitting of mining is allowed.

The bottom line is one simple question: What will be benefit to the owners of the property— the citizens of the U.S? Why should we want a national/internation treasure to be compromised by dust, haul trucks on the highway and noise of generators and blasting that will disturb wildlife and vegetation in the region?

List of Uranium Mines Worldwide

http://dictionary.sensagent.com/List_of_uranium_mines/en-en/

Uranium mining is presently carried out in more than 25 countries around the world. An estimated 100 or more uranium mines in different stages of development are reported. Major uranium mines are located in Canada , Australia and Kazakhstan that contribute more than half of world's uranium production. The largest mines are McArthur River ( Canada ), Ranger ( Australia ), Olympic dam ( Australia ), Krasnokamensk ( Russia ) and Rossing

( Namibia ). The largest uranium producers are Cameco, Rio Tinto, Areva, KazAtomProm and ARMZ-TVEL. The mining methods employed are conventional underground and open cast (62 %), in-situ leaching (ISL - 29 %) and by-product (10%).

Current Operating Uranium Mines = 42

Argentina = 3 mines

Australia = 3 mines (producing 11,000 tons uranium annual)

Brazil = 1 mine

Canada = 3 mines (producing 11,000 tons uranium annual

China = 9 mines

Czech Republic = 1 mine

Germany = 1 mine (producing 77 tons uranium annual)

India = 5 mines (producing 5,000 tons uranium annual)

Iraq = 1 mine

Malawi = 1 mine

Namibia = 2 mines (producing 3,700 tons uranium annual)

Kazakhstan = 3 mines (producing 3,500 tons uranium annual)

Pakistan = 2 mines

Russia = 1 mine producing est.3,400 tons uranium annual)

South Africa = 1 mine

Ukraine = 1 mine

USA = 4 mines (1,650 tons uranium annual)

Current Uranium mines being planned and permitted = 38 mines

Argentina = 3

Australia = 3

Canada = 4

India = 8

Iran = 1

Kazakhstan = 14

Russia = 2

USA = 3

Prospective/proposed Uranium mines = 103

Note that many of these have already calculated the percentage of uranium content.

Algeria = 6

Argentina = 22

Australia = 20

Belgium = 1

Brazil = 1

Canada = 45

China = 6

Kazakhstan = 1

Pakistan = 1

Mines in Arizon :

http://www.wise-uranium.org/upusaaz.html

Arizona 1 mine, Mohave County

Denison Mines began removing high-grade ore at the Arizona 1 mine north of the Grand Canyon in late December [2009], according to the company's president, and trucking it to a mill near Blanding, Utah. The mine is about 45 miles southwest of Fredonia in Mohave County, and about 10 miles from the boundary for Grand Canyon National Park .

On Nov. 10, 2009, Denison Mines Corp. announced that it has made a production decision for its Arizona 1 uranium deposit located in north central Arizona.

The mine will be an underground operation utilizing the existing 1,252 foot deep, 2-compartment shaft and employing a combination of long hole and shrinkage stoping methods at a mining rate of 335 tons per day, four days per week. Ore will be hauled by truck approximately 315 miles to Denison 's White Mesa mill located near Blanding , Utah . The ore will be batch treated in the mill when 17,000 tonnes are available for processing with U3O8 recovery expected to be 95%. Production is expected to total approximately 857,000 pounds U3O8 [330 t U].

Anderson mine, Yavapai County

On March 3, 2009, Concentric Energy Corporation resubmitted its letter of intent to submit an application to the NRC to construct and operate a uranium recovery facility in Yavapai County , AZ. The expected timeframe for the submittal of the application is the third quarter of 2010.

On March 20, 2008, Concentric Energy Corporation provided notice to the NRC that it intends to submit an application to construct and operate a uranium recovery facility in > Download Report of Meeting, July 18, 2006 ![]() (ADAMS ML061940482)

(ADAMS ML061940482)

According to Concentric Energy Corp., former site owner Unocal was planning a huge open pit mine with 38-to-1 strip ratio. They intended to mine 500 million tons of waste rock and leave a huge hole. Such an operation would be most difficult to permit now. However, the property were well suited to be mined by use of conventional coal mining techniques and in-situ leaching of pillars and low-grade material.

Canyon mine, Coconino County

The state Department of Environmental Quality approved an air quality permit for Denison's Canyon mine March 11, 2011.

On Sept. 1, 2009, the Arizona Department of Environmental Quality issued a Discharge Authorization for the 3.04 General Aquifer Protection Permit (APP) 100333 for the Canyon Mine to Denison Mines (USA) Corp.

EZ mine, Mohave County

The state Department of Environmental Quality approved air quality permits for Denison's EZ, Pinenut and Canyon mines this week. It also granted an aquifer protection permit for the EZ Mine. ( Arizona Republic Mar. 11, 2011)

“Jobs” Issue:

One argument that always surfaces when dealing with mining corporations is the issue of the creation of jobs. However, I have been monitoring www.jobcentral.com for the past six months and there have been some 300 mining jobs available in Arizona on any given day. Many have gone unfilled for several months. ASARCO, a union company, does not list its jobs on this website, but personnel at their operation in Hayden stated that they are having a hard time filling their jobs there. So there are unfilled jobs from Kingman, to Globe to Safford and Morenci. We can only conjecture the reasons in a down economy that so many jobs are going unfilled for so many years. First, job-seekers in Arizona are not qualified for the jobs. The second compelling reason is that job-seekers in Arizona do not want to live in isolated areas without services and good schools. Third, job-seekers do not want to take non-secure jobs dependent on the fluctuation of the price of metals. Then the questions arise: Where will the miners live? What will be their water source? What will be the sewer system? These non-technical aspects have to be considered.

Tax Issue:

Another argument for mining is the mining corporations pay taxes. Mining corporations do not pay Federal taxes. I have checked the annual report of Rio Tinto, a huge mining corporation, and they do not pay any taxes. “Like all corporations, we pay no taxes,” a manager of a Rio Tinto operation told me. Neither do mining corporations pay property taxes, certainly not on public lands, but often not on private lands either. They use the “rent-a-cow” methods to escape taxes. This is true of Augusta Resource in Tucson . They pay $10 annual for their 20,000 acre holdings. The taxes paid into the system are the income taxes on the wages of the employees.

Water Issues

The Native Americans in the region need a healthy watershed to continue life on their government-appointed reservations. They have rights to water on their reservation. This right was established in 1908 by Winters v. United States . Another case in 1999 in Arizona regarding water on reservation land reasserted the Federal rights are still in tact. The presiding judge, Noel A. Fidel, wrote, “The doctrine applies not only to Indian reservations, but to other federal enclaves, such as national parks, forests, monuments, military bases, and wildlife preserves.” For entire adjudication, see www.g-a-l.info/AZAdjudication.htm

It is for the purpose of protecting this valuable natural resource that the H.R.644 – Grand Canyon Watersheds Protection Act of 2009 was introduced in House in the 111th Congress by Rep. Raul Grijalva.

While the BLM comprehensive report includes a surprising amount of data on the water in this isolated region, it does not explain how the trees and vegetation are sustained. With water levels at 2,000 ft. obviously, it is not from groundwater. Therefore, it must be from rain and snow, that is, surface water. Exactly what is the number of valuble trees that will be destroyed by the proposed mining operations? If in-situ mining methods are used, how will that effect the surrounding habitat.

When the surface is disturbed by structures, boreholes, fences and access roads, the water flows are disturbed. CWA § 313: Section 313 requires all federal agencies to comply with water quality standards. Federal agencies must ensure that any authorized activity on federal lands complies with all applicable water quality standards. In addition to the EPA water standards used in the Aquifer Protection Permits, Arizona law requires that if any drinking water source is being or is about to be rendered unusable as a drinking water source by a non-hazardous substance, the party must mitigate the situation. [A.R.S. 49-286. Mitigation of non-hazardous releases] See Note 1).

Issues with Conventional Mining:

The BLM Report covers the issues with “on-site” mining. There are issues with mining. Unique problems can occur with the mining process. The release of radon is often associated with uranium mining. A good example is the on-site mining violations of Denison Mining Corporation at their La Sal Mine in Utah . Note that Denison was not submitting the required monthly reports. [See No. 21 and 32 below]

Denison Mine ( USA ) Corp.

EPA Notice of Violation

Violation of Clean Air Act

Docket No. CAA-oS-2010-o016

August, 2010

Underground uranium mining by the Respondent results in emissions of radon-222 to the outside air. The primary sources of these emissions are vents from the underground mine to the surface.

FINDINGS OF FACT

18 . The La Sal Mines operation is an "active underground uranium mine" subject to the requirements ofthe NESHAPs for Radon Emissions for Underground Uranium Mines found at 40 C.F.R. Part 61, Subpart B.

19 . In March 2010, Denison Mines submitted the Annual Compliance Report for 2009 to EPA as required under Section 61.24(a).

20. The Annual Compliance Report demonstrated that in 2009, the following receptors received an effective dose of radon-222 exceeding the emission standard of 10 mrcm/yr.

21 . Denison Mines has not submitted monthly reports to EPA pursuant to Section 61.24(b).

22 . On April 27, 2010, EPA staff inspected the La Sal mines. EPA has also reviewed records received from Denison Mines regarding the La Sal mines operations.

23 . During the inspection, Vent 1350 was observed to be venting to the atmosphere withoutmonitoring. Records show that the vent was venting from April 18 - 27, 2010 without monitoring.

24. Records show that Vent 1350 was also venting to the atmosphere without a monitor on

January 12 through february 15,2010; and March 31 through April 8, 2010.

25. The vents named Pandora 3, Pandora 7, and Pandora 12 are naturally venting shafts that vent in or out based on atmospheric and mine conditions. Records show that the vents did not have monitors from January through April, 20 I O.

26 . Denison Mines has been using Test Method A-7 for the analysis of radon-222 since approximately January 2009. Denison Mines has not received approval from EPA to use Test Method A-7 in lieu of Test Method A-6.

27. On March 30, 2010, Denison Mines requested approval from EPA to use the AERMOD computer model in lieu of COMPLY-R to demonstrate compliance with the emission standard at the La Sal mines.

28. On April 26, 2010, Denison Mines requested approval from EPA to use Method A-7 to measure radon from the vents at the La Sal mines.

29 . On July 21, 20 I0, EPA denied Denison Mines' request to use Method A-7 for measuring radon emissions because it failed to submit any Method A-6 data as required by the regulations and therefore failed to demonstrate that the Alpha Track Detectors used by Denison mines applying Method A-7 produce data comparable to Method A-6. 5

30 . On July 21, 2010, EPA also denied Denison Mines' request to use the AERMOD computer model to demonstrate compliance with the emission standard due to concerns regarding the accuracy of the input data used for the direct comparison the AERMOD and COMPLY-R computer models.

FINDING OF VIOLATIONS

31. Emissions of radon-222 from the La Sal mines during 2009 exceeded the emission standards for six receptors, in violation of40 C.F.R. § 61.22 and Section 112 of the CAli .

32. Denison Mines has not submitted monthly reports following the emissions exceedances of radon-222 for the year 2009, in violation of 40 C.F.R. § 61.24(b) and Section 112 of the CAA

33. Emissions ofradon-222 from Vent 1350, Pandora 3, Pandora 7, and Pandora 12 have not been continuously measured, in violation of 40 C.F.R. § 61.23(a) and Method 115, andSection 112 of the CII.A.

34 . Test Method A-7 has been used to analyze radon-222 in lieu of Test Method A-6 at the La

Sal mines, without prior approval from EPA, in violation of 40 C.F.R. § 61.23(a) and

Method I 15, and Section 112 of the CAA.

NOTICE OF VIOLATIONS

Notice is given to Denison Mines (USA) Corp. that the Administrator of the United States Environmental Protection Agency, by authority duly delegated to the undersigned, finds that Denison Mines (USA) Corp. is in violation of Section 112 of the CAA and its implementing regulations, as set forth in the Finding of Violations.

Issues with In-Situ recovery:

Because of the presence of perched water or closed aquifers, there is a potential of the use of in-situ recovery of the uranium.

Chemicals used in in-situ mining

Solution mining is usually carried out by drilling inflow wells into the ore body upstream of a production well based on the direction of groundwater flow. Salt solutions of ions, such as sulfate, bicarbonate, carbonate, and amonium known to form stable aqueous complexes with hexavalent uranium, are pumped to the inflow well, and simultaneously, there is a withdrawal of a slightly greater volume of water from the production well. A solution of oxidant (NaClO 3 ) may be added to increase leaching efficiency. The inflow of solution is continued until the leach zone is depleted, as indicated by a decrease in uranium concentration in the leach solution.

There are issues with the transport and storage of chemicals, which is discussed below.

It is impossible to keep a stable solution in the dissolved radiation in the in-situ wells. Therefore, the uranium that was mostly bound up in pibes is now released. What will be the effect on the surronding trees and vegetation?

Although the example is Texas is a much bigger operation, it does give an indication of the problems created in the groundwater by in-situ recovery. Although the report centers on the failure of the Texas Dept. of Environmental Quality to hold the mining company to its original water standards, it backs up the allegation with lots of tables of how not only uranium and radium 226 levels rose in the aquifer, but also levels of arsenic, sulfate and other metals.

http://www.mining-law-reform.info/TexasUraniumReport.pdf

Issues with Milling/Processing

Although at present, the ore is trucked to Blanding , UT , it is feasible if more mines were to open, the mining companies would put a milling operation in the Grand Canyon region to avoid the 250 to 300 mile trip. This heavy use of fossil fuel is one of the issues with the claim that nuclear power is clean energy. Therefore, it is essential to understand the ramifications of a milling operation. Exporting an environmental problem elsewhere is no reason to eliminate its consideration.

Chemicals used in processing:

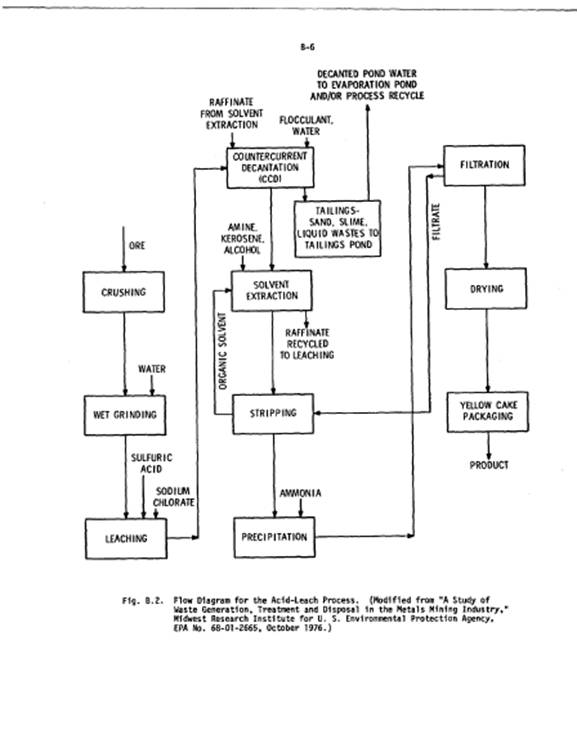

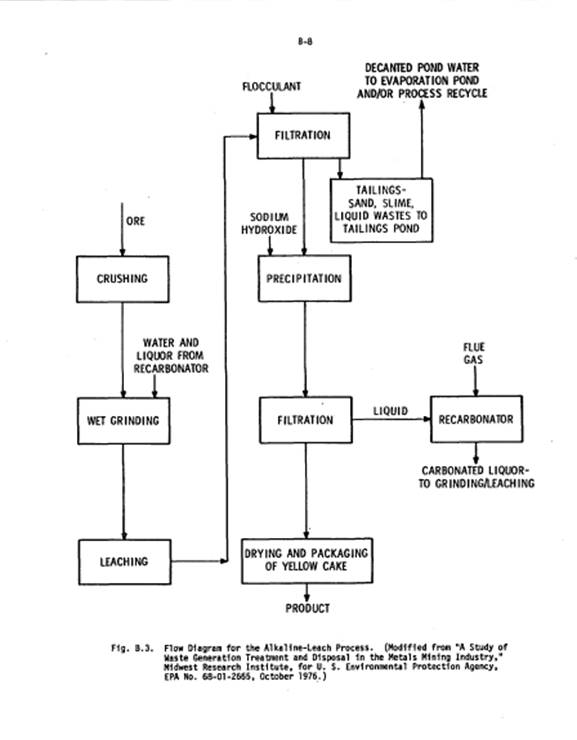

There are two major process schemes for conventional mills: acid and alkaline leaching.

Acid leaching is done with sulfuric acid, while alkaline leaching uses carbonate and bicarbonate. For the further processing, there exists a variety of processes, each step requiring more reagents:

Sulfuric Acid

Ammonia

Ammonia Sulfate

Sodium Chlorate

Sodium Carbonate

Hydrogen Peroxide

Kerosene

Amine

Isodecanol

Sodium Hydroxide

Flocculent Polymer

See Figures below for processing flows:

Acid-Leach Process

Alkaline Leach Process

Certain solvent extraction reagents, such as Kerosene, pose a severe fire hazard, as Western Mining Corp. (Australia) had to experience the hard way—twice—at its Olympic Dam mill in South Australia :

Fire at Olympic Dam copper/uranium mill

On 23 December 1999, a fire at the Olympic Dam solvent collection pond adjacent to the solvent extraction plant interrupted power to the mine, plant and Roxby Downs township. Employees in the area were evacuated and there were no injuries.

WMC and CFS fire crews contained the fire to the solvent extraction area. It started shortly after 7.30 pm and burned until about 3 am the next day. A fireball could be seen from 25 km away.

Uranium production will be down 200 tonnes to about 4,100 tonnes in the year 2000 because of a temporary loss of some solvent extraction facilities.

According to WMC corporate affairs manager Richard Yeeles, "there are no radiation issues associated with the fire". (WMC, The Australian 24 Dec. 1999)

Fire again at Olympic Dam copper/uranium mill

A fire involving about one million litres of kerosene broke out just after midday on 21 Oct., 2001, at the solvent extraction plant of WMC's Olympic Dam copper/uranium mine. The blaze was contained just before 3:30pm. The fire is in the same area as a blaze on 23 Dec., 1999, that caused A$10 million worth of damage. (ABC News 21 Oct 2001)

The new fire caused damages above A$20 million. During the rebuilding period, the mine's annual uranium output would fall by 1500 tonnes from 4500 tonnes. (News Limited 23 Oct 2001)

WMC believes "the most likely cause was a static electricity discharge at a location where polyethylene piping carries a kerosene-like solvent." (WMC 13 Feb 2002)

http://www.wise-uranium.org/umopauod.html#OLYMPICDFIRE

http://www.wise-uranium.org/umopauod.html#OLYMPICDFIRE2

One of the more advanced mill projects is Piñon Ridge. It involves sulfuric acid leaching and kerosene-based solvent extraction (see attached excerpts from license application, more details can be found in the application documents).

Chemical spills and releases to the environment

Not only do the ores have to be trucked over hundreds of miles for processing, the chemicals have to be shipped to the milling site. This was a continual problem at the Bagdad, Arizona copper mine. Plus there are spills and equipment breaks that release the chemicals to the environment. From approximately 1987 to 2003, the Arizona Department of Environmental Quality posted hazardous spill report summaries on the Internet. In 2003, due to staff shortage they discontinued this service; however, we do have 15 years of data from mines in Arizona . The principal hazardous waste was sulfuric acid, which is used to leach copper.

Note that I only compiled the information from mines in Pima County and Bagdad mining operation because of the numerous transport accidents.

Arizona Department of Environmental Quality Records

Summary of Sulfuric Spills at Sierrita Copper mine, Pima County , Arizona

—All spills were on-site

9/06/05 8,058 lbs. Sulfuric Acid (Report)

9/24/05 1,000 lbs. Sulfuric Acid (Report)

4/19/03 8,722 lbs. Sulfuric Acid

2/5/02 39,375 gals. Sulfuric Acid

7/3/01 1,209 lbs. Sulfuric Acid

5/22/00 5,350 gals. Leach Solution (Sulfuric acid/Copper)

5/05/98 40,000 gals. Leach Solution (Sulfuric acid/Copper)

5/04/98 120,000 gals. Leach Solution (Sulfuric acid/Copper)

3/29/97 8,000 lbs. Sulfuric acid-93%

7/11/97 2,798 lbs. Sulfuric acid

7/22/96 3,000 lbs. Sulfuric acid

8/11/96 100 gals. Sulfuric acid

6/12/96 13,263 lbs. Leach Solution (spent electrolyte)

3/23/96 3,000 lbs. Sulfuric acid

2/21/96 1,850 lbs. Leach Solution (spent electrolyte)

1/10/96 2,000 lbs. Sulfuric acid

1/8/96 4,000 lbs. Sulfuric acid

12/19/94 5,000 gals. Leach Solution

11/03/94 7,000 gals. Sulfuric acid

9/19/90 2,000 gals. Diesel fuel

3/16/90 1,500 gals. Hydrochloric acid

9/8/88 10 gals. PCB's

Summary of Spills at Bagdad Copper Mine, Yavapai County, Arizona

The Hazardous Waste Incidents at Bagdad mine are of particular interest for a proposed mine that will need to truck in various chemicals to a smelter. These spills of extremely toxic chemicals and copper concentrate seriously impact the roadways and soils, as well as potentially pollute ground or surface water, on Forest Service, BLM and State Trust Land . Apparently, there was a winding road to the railroad junction, and eventually another route was used, which did reduce the off-site spills. Again, the records are though 2001 with two reports in 2004 that were scanned from reports copied from ADEQ records.

http://www.savethesantacruzaquifer.info/Hazardous%20Material%20Incident%20Bagdad.htm

Date Amount Chemical Land released to

12/07/04 7,484 lbs. Leach Solution On-site (Report

9/10/04 354 gals. Sulfuric Acid On-site (Report)

12/04/00 <200 gals. Sulfuric Acid State

9/18/00 5,850 gals. Xanthate Federal

3/11/99 misc Cyanides, Acids Federal

3/07/99 12,000 gals. Effluent (treated ww) Federal

3/01/99 200 gals. Sulfuric Acid State

7/27/98 ? Sulfuric Acid State

1/01/98 50,000 lbs. Copper Concentrate State

12/12/97 40,000 lbs. Copper Concentrate State

9/17/97 7/7200 lbs. Sulfuric Acid On-site

6/11/97 50,000 lbs. Copper Concentrate Bagdad town

3/09/97 1,500 lbs. Sulfuric Acid On-site

7/18/96 3.57 lbs. Mercury Bagdad town

6/18/96 3/40,000 lbs. Copper Concentrate State/Private

8/31/95 35,000 lbs. Copper Concentrate State

7/21/95 48,100 lbs. Lead Sulfide/Cu Conc. County

11/22/94 2,100 gals. Diesel fuel County

3/02/94 60 gals. Sulfuric Acid State

6/11/93 600 gals. Sulfuric Acid State

5/26/93 200 gals. Diesel Private prop

2/22/92 1,200 gals. Sulfuric Acid On-site

5/09/91 ? Sodium Cyanide State

9/18/90 13 gals. PCB On-site

12/17/87 1,500 gals. Sulfuric Acid State

11/09/87 2/2,500 gals. Sulfuric Acid State

9/20/86 50-60 gals. Sulfuric Acid State

ASARCO Silver Bell mine, Pima County

http://www.savethesantacruzaquifer.info/Hazardous%20Material%20Incident%20Silverbell.htm

10/19/06 90,000 gals Raffinate (copper solution)

11/23/02 242,000 gals Sulfuric Acid (equipment failure, pond overflowed)

Environmental Protection Agency Records

Annual Toxics Release Inventory reporting began in 1987 after the enactment of the Emergency Planning and Community Right-to-Know Act of 1986. The inventory provides information to the public on annual toxic chemical releases reported by certain industrial and federal facilities. The TRI does not include data on toxic emissions from cars and trucks, nor from the majority of non-industrial sources, such as agriculture. In 2000, TRI expanded to include persistent bioaccumulative and toxic chemicals, or PBTs, at ranges from 0.1 grams to 100 pounds. PBT pollutants are toxic chemicals that remain in the environment and food chain, posing risks to human health and ecosystems.

http://yosemite.epa.gov/opa/admpress.nsf/0/a8fe76d2741b011b852577fb005a7883?OpenDocument

The top facilities in Arizona for total on-site and off-site releases during 2009 of all chemicals (reported in pounds) are:

|

Facility Name |

City |

Total Releases |

1 |

Asarco LLC Ray Complex/Hayden Smelter & Concentrator |

Hayden |

20,996,567 |

2 |

Freeport-McMoran Miami Inc |

Claypool |

20,423,690 |

3 |

Springerville Generating Station |

Spingerville |

2,635,628 |

4 |

Freeport-McMoran Sierrita Inc |

Green Valley |

2,421,465 |

5 |

Cholla Power Plant |

Joseph City |

2,227,390 |

6 |

Coronado Generating Station |

Saint Johns |

2,115,187 |

7 |

Salt River Project Navajo Generating Station |

Page |

2,060,692 |

8 |

Asarco LLC Mission Complex |

Sahuarita |

1,756,420 |

9 |

Freeport-McMoran Morenci Inc |

Morenci |

1,272,976 |

10 |

Freeport-McMoran Bagdad Inc |

Bagdad |

1,180,367 |

http://www.epa.gov/region9/toxic/tri/report/09/TRI-2009ArizonaReport.pdf

Contaminants in Soil:

In my previous comments on April 4, 2011 [www.mining-law-reform.info/GrandCanyon.htm], I included data regarding the problems with water quality at the local Sierrita mining operations in Green Valley .

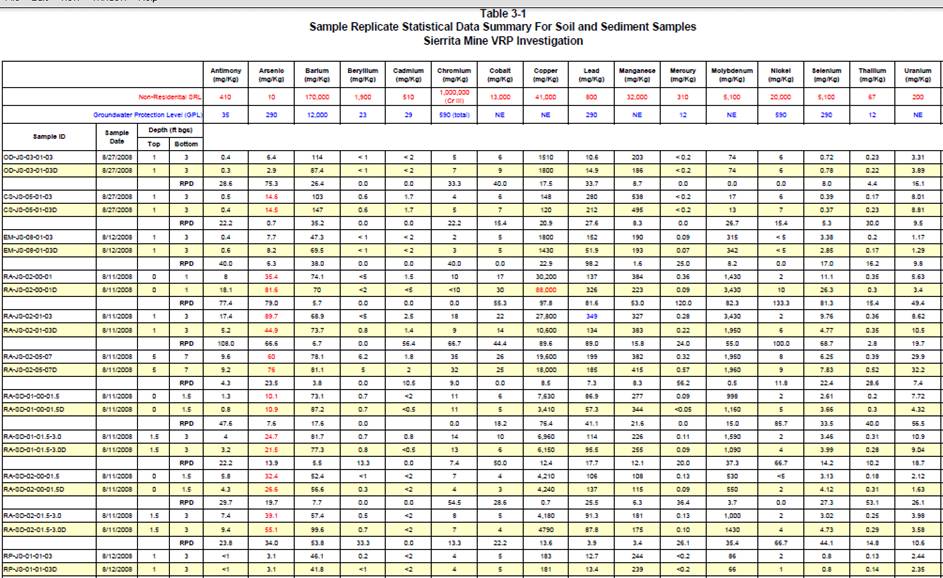

Sierrita is on a mandated Voluntary Remediation Program, but they have not completed the water quality data to augment the information of the radiochems in the groundwater outside the mine's operations that I previously submited. However, they have completed their analysis of the discharge of toxic heavy metals to the environment.Metals, such as uranium, arsenic, selenium, chromium are inert and stable while bound in the bedrock. However, when they are disturbed by mining, milling and processing, the metals are dispersed to the environment via dust and water. The waste material must be disposed of in the environment. It contains whatever heavy metals are in the region and Arizona has high levels. This is affirmed by the fact that when EPA did its extensive investigation of TENORM: Technologically Enhanced Naturally Occurring Radioactive Materials, they used the mines in Arizona for their study and report. http://www.epa.gov/rpdweb00/docs/tenorm/402-r-99-002.pdf

The following is an exact copy of the evaluation section of the 1,000 plus page report.

http://www.fcx.com/sierrita/pdf/2011/040411_reports.pdf

FINAL VOLUNTARY REMEDIATION PROGRAM (VRP)

SOIL AND SEDIMENT CHARACTERIZATION REPORT

FREEPORT-MCMORAN SIERRITA INC.

GREEN VALLEY, ARIZONA

MARCH 2011

Abbreviations used in report:

ADEQ – Arizona Department of Environmental Quality

COI – Constituent of Interest

COPC - Constituent of Potential Concern

GPL – Groundwater Protection Level

SRL – Soil Remediation Level

r-SRL – Residential Soil Remediation Level

nr-SRL – Non-Residential Soil Remediation Level

VRP – Voluntary Remediation Program

Table of Results: Page 3.1

4.0 RESULTS EVALUATION (Page 4-1, Page 87 of .pdf)

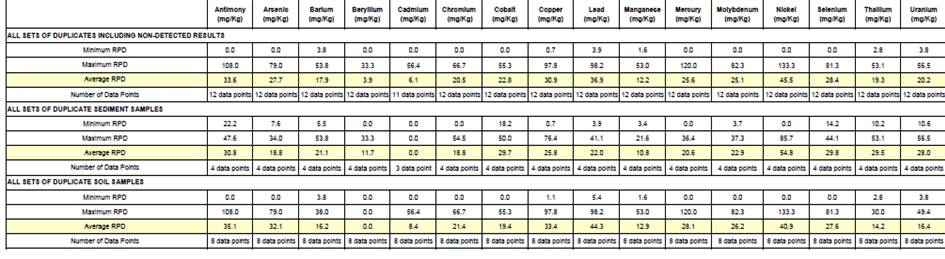

The following sections present an evaluation of the analytical results of the VRP soil and sediment investigation. The subarea characterization data were evaluated by comparing the concentrations of each COI in soil and sediment to its nr-SRL (ADEQ 2007) and soil GPL (ADEQ 1996).

The nr-SRL values are risk-based concentrations considered protective of direct contact occupational exposures to chemicals in soil (e.g., soil ingestion, inhalation, and dermal contact). Specifically, nr-SRLs are concentrations in soil that a worker could be exposed to every working day for 25 years without adverse health effects….

4.2 Evaluation of Sites with nr-SRL Exceedances (Page 4.2, Page 88 of .pdf)

Per EPA guidance, risk-based screening levels are used to identify those sites requiring further evaluation. Exceedance of risk-based screening levels does not indicate inherent risk at a site, but suggests that further evaluation of the site's COI concentrations is necessary. This section discusses the results of the evaluation of the direct contact pathway for subareas where nr-SRLs are exceeded.

The most likely potential exposures to COIs in soil are through direct contact by site workers. The Former CLEAR Plant, Former Esperanza Mill Area, Former C Pond and Spoils, Old “D” Pond, Former Raffinate Pond, and the Former Laydown Yard were further evaluated because nr-SRLs were exceeded in at least one sample at each of these sites.

The soil and sediment data were further evaluated by calculating the 95 percent upper confidence limit on the mean (95UCL) using surface soil data for each subarea. For risk assessment purposes, the ADEQ (Hanley 2010) considers surface soils to occur from 0 to 15 ft bgs. Soils below 15 ft bgs are considered subsurface soils (Hanley 2010). The 95UCL were calculated using ProUCL Version 4 (EPA 2007). Table 4-2 and the following bullets summarize the results of this evaluation.

• Former CLEAR Plant Subarea– Arsenic, copper, and lead were detected at concentrations in soil that exceeded the nr-SRL. The maximum arsenic concentration is 17 times greater than the nr-SRL, and exceeded the nr-SRL in 22 (24 percent) of the samples collected in the subarea. In addition, the 95UCL of 23.1 mg/kg, calculated exceeded the nr-SRL of 10 mg/kg. Therefore, arsenic is tentatively identified as a constituent of potential concern (COPC) at the Former CLEAR Plant.

Copper and lead concentrations exceeded the nr-SRL, ranging from four samples (4 percent) to two samples (2 percent), respectively. The maximum copper and lead concentrations exceeded the nr-SRL by a factor of three and two, respectively. The calculated 95UCL values for copper and lead were below their respective nr-SRLs (Table 4-2). Therefore, copper and lead are not present at concentrations in soil and sediment that represent a health risk for non-residential populations in the Former CLEAR Plant subarea and are not considered COPCs.

• Former Esperanza Mill Subarea – Arsenic concentrations in soil at the Former Esperanza Mill subarea exceeded its nr-SRL (Table 4-2). The maximum arsenic concentration is one order of magnitude (10 times) greater than the nr-SRL, and exceeded the nr-SRL in eight (19 percent) of the samples. The calculated 95UCL (19.4 mg/kg) also exceeded the nr-SRL (10 mg/kg; Table 4-2). Therefore, arsenic is tentatively identified as a COPC in the Former Esperanza Mill Area subarea.

• Old D Pond Subarea – A single arsenic result (10.6 mg/kg) slightly exceeded its nr-SRL (10 mg/kg). The arsenic nr-SRL was exceeded in 1 (5 percent) of the samples collected in the subarea. The 95UCL value (4.38 mg/kg) calculated for arsenic is below the nr-SRL (10 mg/kg; Table 4-2). Therefore, arsenic is not present in soil in this subarea at concentrations that represent a health concern for non-residential populations and are not considered COPCs.

• Former C Pond and C Pond Spoils Subarea – Arsenic and lead concentrations in soil at the Former C Pond and C Pond Spoils subarea exceeded their respective nr-SRLs. The maximum arsenic concentration exceeded the nr-SRL by a factor of two, and the nr-SRL was exceeded in four (10 percent) of the samples collected at the Subarea. Lead exceeded the nr-SRL in one sample (2 percent) by a factor of five.

The 95UCL values calculated for arsenic and lead are below the nr-SRLs (Table 4-2).

Therefore, neither arsenic nor lead is present in soil in this subarea at concentrations that represent a health concern for non-residential populations and are not considered COPCs.

• Former Raffinate Pond Subarea – Arsenic and copper concentrations in soil and sediment at the Former Raffinate Pond subarea exceeded its nr-SRL. The maximum arsenic concentration was nearly one order of magnitude (10 times) greater than the nr-SRL and exceeded the nr-SRL in 18 (64 percent) of the samples. In addition, the calculated 95UCL (38.3 mg/kg) also exceeded the nr-SRL (10 mg/kg). Therefore, arsenic is tentatively identified as a COPC in the Former Raffinate Pond subarea.

Copper exceeded the nr-SRL in 1 sample (4 percent) by a factor of two. The 95UCL calculated for copper of 16,589 mg/kg was below the nr-SRL of 41,000 mg/kg (Table 4-2). Therefore, copper is not present in soil at the Former Raffinate Pond at concentrations that represent a health risk for non-residential populations. Therefore copper is not considered a COPC.

• Former Laydown Yard – Arsenic, lead, and molybdenum concentrations in soil exceeded the nr-SRLs. The maximum arsenic concentration is six times greater than the nr-SRL and exceeded the nr-SRL in 10 (63 percent) of the samples. In addition, the calculated 95UCL (19.0 mg/kg) also exceeded the arsenic nr-SRL (10 mg/kg). Therefore, arsenic is tentatively identified as a COPC at the Former Laydown Yard subarea.

Lead and molybdenum exceeded the nr-SRLs by less than a factor of two. Lead exceeded the nr-SRL in one sample (6 percent); molybdenum exceeded the nr-SRL in four samples (25 percent). The 95UCL values calculated for lead and molybdenum are below their respective nr-SRLs (Table 4-2). Therefore, lead and molybdenum are not present in soil at concentrations that represent a health risk for non-residential populations in the Former Laydown Yard and are not considered COPCs.

. . . . . . . . . . . . . . . . .

4.3 Evaluation of Sites with GPL Exceedances

This section discusses the results of the evaluation of the soil to groundwater migration pathwayfor subareas where GPLs are exceeded. To evaluate the groundwater migration pathway, COI concentrations in soil were compared to GPLs. Table 4-3 summarizes the COIs detected in soil at concentrations greater than their respective GPLs.

Antimony and lead were the only COIs detected in soil or sediment at concentrations greater than their respective GPLs. Antimony exceeded its GPL in the Former CLEAR Plant and the Former Esperanza Mill subareas. Lead exceeded its GPL in the Former CLEAR Plant, the Former C Pond and C Pond Spoils, Former Raffinate Pond, and the Former Laydown Yard subareas.

As with direct exposure to soil, the 95UCL represents a broader range of the concen-trations that would likely leach to groundwater because leaching occurs over a generalized area, not at a single location within a site. The 95UCLs calculated for antimony and lead in all of the subareas were below the GPLs, with the exception of the 95UCL for lead in the Former Laydown Yard subarea which was slightly greater than the GPL by about 1.2 times (Table 4-3).

Five soil samples containing the highest lead concentrations (ranging from 303 to 3,740 mg/kg) were submitted to the laboratory for SPLP extraction and total lead analysis of the resulting leachate. The leachate concentrations of these samples contained lead at concentrations ranging from less than the reporting limit (0.0005) to 0.001 mg/L. An alternate GPL for lead was calculated using the highest SPLP result of 0.001 mg/L in accordance with A Screening Method to Determine Soil Concentrations Protective of Groundwater Quality , (ADEQ 1996). The alternative GPL for lead was calculated at 54,772,300 mg/kg, well below any detected lead concentrations in soil in any of the subareas.

______________________________________________

Thank you for your time and attention to this very complicated matter. And thank you for caring!

________________________________________________________________________

Note 1) Sherman Alexie, author of The Lone Ranger and Tonto Fistfight in Heaven

http://eng254project.webs.com/uraniummining.htm

Uranium Mining has affected many aspects of modern Native American life deeply and Sherman Alexie's Spokane Indians are not immune to these problems. Washington State 's only uranium mines are on the Spokane Indian Reservation. These are the Sherwood Uranium Mine and the Midnite Uranium Mine. Sherwood Uranium Mine completed its cleanup in 2004 on Spokane tribal lands. They were successful. The Midnite Uranium Mine, which is eight miles from the main tribal complex and firmly on Spokane Indian Land, contributes to the heavy metal contamination (including, but not limited to: Arsenic, Barium, Cadmium, Chromium, Lead, Cobalt, Aluminum, Zinc, Uranium, etc.) of Blue Creek. Radioactive isotopes also contaminate groundwater, including Blue Creek. Blue Creek flows into the Spokane River , then into Lake Roosevelt . This should worry the federal government, but no action has been taken. Why?

After the development of the atomic bomb and WWII, Western countries developed policies dealing with human exposure to radiation, with the United States adopting policies mostly organized by the British government in the 1940's. There have been no long-term health problems in any of these Western countries, except in cases of the Native American mining communities. Why? They are considered “independent” of the federal government and therefore, the cleanup falls on the EPA. The EPA's hands are tied because they are suing Midnite Mine's parents company for the cleanup costs. Meanwhile, people on the Spokane Reservation are dying.

Dawn Mining Company left behind almost 2.4 million tons (estimated) of stockpiled ore when they closed operations at Midnite Mine in 1981, about 2 million tons of this ore is estimated to be uranium oxide. The Mine also tore up Reservation land, with Dawn Mining Company leaving behind nearly 33 million pounds of waste rock when they closed operations at the site. All of this waste ore and rock causes not only acid mine drainage, which also flows into Blue Creek, but causes high levels of radiation in the Spokane River along with heavy metal contamination. Of the six mining pits left behind as scars on the land, two are part-way filled with groundwater that poisons the land around it.

Recently, the Midnite Mine was designated as a federal “Superfund site”; estimates for cleanup of the Mine are around 152-280 million dollars. Work has not been started because the EPA cannot force the parent company of Dawn Mining Company to fund the cleanup. Therefore, when the cleanup eventually happens, it will be on the taxpayer's funds instead of the people who caused the problem in the first place. According to mining-law-reform.info:

“The Midnite Mine operated from 1955–1981 under the ownership of a subsidiary of Newmont Mining Company: Dawn Mining Company. Today the mine looks like an open wound in the heart of the Spokane Indian Reservation. Dawn abandoned the pits and 33 million tons of waste rock they created without conducting reclamation work to either rehabilitate the site or prevent release of pollutants. As a result, radionuclides, heavy metals and other pollutants have spread several miles beyond the mine site, leaving a toxic trail in downstream creeks and valleys and in downwind plants and hillsides in the central part of the Spokane Indian Reservation.”